Tensile Structure Installation

Lets build something incredible together...

Installation is the most pivotal stage of constructing a new building. At Collinson Tensile, you can be assured that our experienced installation team will be attentive, helpful, and thorough and provide an efficient service, providing a building you are completely happy with and one that helps your organisation achieve its goals.

One of the many benefits of tensile fabric buildings is a shorter installation period than in traditional construction. Our expertise in tensile buildings, and our offsite construction capabilities, mean we can create high-quality industrial spaces that are quick to build, easy to maintain, and allow you to maximise the space you have available.

We have decades of experience in the design, construction and installation of buildings and have been the trusted UK contractor for Best-Hall for over 20 years.

As the sole UK distributor and installer for Best-Hall tensile buildings, we use tried and trusted technology to create safe, reliable, and cost-effective industrial spaces for our clients.

Tensile Membrane

- The steel frame is covered using Serge Ferrari membranes which are recognised globally as the market leaders in architectural membranes.

- This ensures longevity in performance and visual appearance.

- Patented Precontraint technology places the base textile under bi-directional tension during the complete manufacturing process.

- Proven longevity: the thicker coating provides greater protection to the base textile and greater mechanical resistance characteristics.

- Anti-Wicking: conventional covers allow water capillarity whereas Serge Ferrari technology prevent this action which will harm the membranes performance and appearance over time.

- Limited Creep: Precontraint tech ensures significant reduction in the creep phenomenon which is 3 to 4 times higher for conventional fabric membranes.

- In reality this means our membrane cover will not stretch and will remain drum tight over its life compared to other membranes.

- This enhances the life span and reduces risk of wear & tear.

- Tensioning system: The BestHall tensioning system has been proven over many decades of use and development to ensure the membrane remains fully in tension throughout its life and does not require re-tensioning or adjustment throughout its lifespan unlike other solutions.

Steel Frame

- We use only European SSAB and Tata Steel to ensure the highest possible quality as European standards ensure a stronger steel is produced, which is essential for buildings.

- For a superior finish, our steel frames are powder coated at our in-house automated paint line. This provides a smooth surface, minimising friction between the PVC cover and the frame, thereby reducing abrasive wear on the cover.

- The environmentally friendly and aesthetically appealing powder painting also gives the frame excellent corrosion protection even up to class C5, if needed.

- Every structure is individually designed and engineered based on the environmental, wind and snow loads of the buildings location, ensuring a robust and reliable building solution.

- As the market leader in quality, Best-Hall has received the European CE marking for its load-bearing structures. In accordance with the quality system, all materials are traceable, tested and equipped with a material certificate. Best-Hall’s designers also have the qualification of a designer of steel structures grade “PV” granted by FISE, which is the highest level possible for designing steel structures.

Specification

- Steelwork Treatment – Shot blasted Sa 2,5 and Powder Coated to meet the standard SFS-EN ISO 12944-2 C3/C4/C5 class of exposure.

- Colour: Light Grey or White

- Execution class EXC2 according to SFS-EN 1090-2.

- CE-marked steel frame.

- Consequence class CC2.

- Tensioning & Cross buckling CHS/SHS elements are manufactured from Magnelis®

- Structural Tolerances according to Eurocodes: L/300 and H/150

Special load case

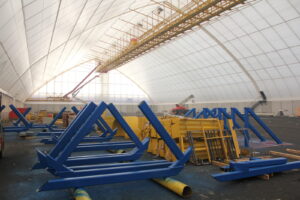

In addition to the wind/snow loads we can also design the building to withstand additional loads from ancillary equipment such as conveyors or other heavy items as needed. Photo shows roof mounted conveyors supported by our steel frame (note building also has our optional inner liner system)

Start a Project